|

Search this site for keywords or topics..... | ||

Custom Search

| ||

Hot Frames

Hot frames pick up where cold frames, hoop houses and unheated greenhouses leave off. As the name implies, these structures provide steady, moderate heat to a contained growing environment. We’ve already seen on other pages about how to provide a contained growing environment. So, how is the heat provided, and how much, and for how long? Those questions are at the heart of the difference between hot frames and other germination and horticultural heat sources.

What Are They, and Why Are They Used?

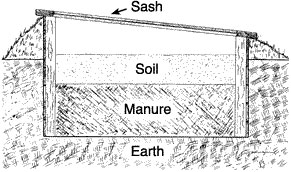

As we saw with cold frames, hot frames have been around a long time. And they traditionally harnessed a heat source that was, until recently, in plentiful supply on most farms. Namely, animal manures. The fresh manures would be collected in sufficient quantity for the size of the intended frame, right before the frame was built. While the manures were being collected, the frame’s footprint was excavated down well below ground level, then covered to keep dry. Once the manures were collected, they would quickly be put into that excavated space and allowed to begin composting. That composting process is what provided the heat for old-fashioned frames. A layer of fertile soil would go over the manure pack so that seedlings wouldn’t be in direct contact with the compost. After that layer was in place, either seeds could be planted directly in that soil, or transplants could be placed in the soil for further growth.

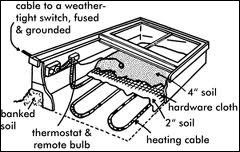

Fast forward to recent years, and now growers have a few more options. Soil heating cables and various hot-water plumbing systems have become very common for in-ground heating, and under-bench radiators or on-bench heating mats have become common in greenhouses. Whichever form of heat is selected and used, the principle is the same - providing moderate, steady heat at the root zone can dramatically speed up germination and growth, even when surrounding air temps are much lower.

Advantages and Disadvantages

The first major advantage is the issue of regular, sustained, controlled heat. Regardless of the heat source, hot frames proactively provide regular predictable heat, night and day, for weeks at a time. Compare that to cold frames, hoophouses and unheated greenhouses which passively collect variable environmental heat. If the sun doesn’t shine, those passive collectors don’t have much to work with. If the sun is bright, those passive collectors can collect too much and the heat must then be vented. But with hot frames, the heat is just right, all the time.

A second advantage to traditional hot frames is that the composting manure stays in the trench or excavated space, thus providing permanent soil improvements. Some traditional market garden plans counted on this method as one of their main soil fertility management tools. The planting bed would be heavily manured once every three or four years, and that manuring event would coincide with the use of hot frames. The crops planned for that bed would be those which were tender and/or valuable enough to warrant the bed’s extra heat. Managing a large garden or market crops area in this way would help coordinate the fertility, the crop rotation, and the cost-effective use of these structures from year to year.

An advantage of more modern heating methods is that heating cables and radiator systems can be turned off and on very easily, unlike the composting process. If the crop is coming along nicely, the weather has settled and the extra heat really isn’t needed, the system can be turned off. Or conversely, an extended cold spell would simply mean running the system a little longer than planned. That’s nice system flexibility during crucial and notoriously unreliable early season periods.

The biggest single disadvantage to the traditional hot frame method, is access to and reliance upon manures. Many modern farms and gardens no longer have regular access to large quantities of animal manure. In some jurisdictions, they can't use those products even when they have access to them. Under the new Food Safety Modernization Act (FSMA) and Good Agricultural Practices (GAP) certification rules, the use of raw animal manures buried well below the surface, with a good depth of soil over the top, SHOULD be OK, since the veggies aren't in direct contact. But I'm willing that the use of traditional hot frames on commercial farms, would raise the eyebrows of any FSMA or GAP inspector, and possibly jeopardize certification under either set of rules. However, the use of soil heating cables, hot water radiators, etc would not share that risk. Each grower will have to determine how best to juggle the benefits to the land, versus the regulatory issues.

Beyond all that, the second disadvantage to this approach involves the size and weight of the structure itself. Unlike cold frames, hot frames in particular need to be fairly substantial, so that they can hold in the heat. They also need to be relatively large, to maximize the quantity of plants within versus the cost of heating that space. For those two reasons, hot frames are typically not portable. Thus, a garden or working veggie farm needs to have a dedicated space for hot frames, which may prove to be problematic. If a grower wants to make the most of buried manure as part of the ongoing soil fertility program, the frames will have to be built ruggedly enough to hold in heat, yet still be portable. That will take some careful planning. If that's not a huge concern, then the frame can be built as heavily, and/or to whichever size, is desired. Ironically, if soil cables or hot water radiators are used, they also may limit the placement and movement of the frames from year to year. So this aspect needs to be carefully considered.

How To Use

Most of the frame/lid materials and construction issues listed in the cold frames description would apply to hot frames as well, so I won’t repeat them in detail here. Suffice to say that a variety of materials can be used, along with a variety of designs. The grower can evaluate his/her size needs, budget, affordable materials and even free materials when designing the shell. Construction can be as elaborate, or as simple, as the grower chooses. That being said, the traditional design does feature the excavated space below the final ground level. That extra space would be filled by the fresh manure. Some growers build their frames such that the manures are contained by walls of raw earth, to maximize the movement of water, worms and other soil life. Other growers want to insulate the inside of the shell, and/or protect against intrusion from the outside - soil-living insects, greedy tree roots, runoff from a nearby water source, and small animals like voles. The grower would need to decide whether their structure's walls need to extend down to the bottom of that excavated depth, or merely sit on top of it. There is no one right answer; it’s whatever works best for the combination of circumstances. For those growers who choose to use heating cables or radiator pipes, that’s not such a big design issue but growers should still consider whether one design or the other might offer desirable advantages.

Careful consideration should be given, however, to the heat source. If animal manures are easily and cheaply available, that can be an extremely cost effective heat source. It does require more manual effort to dig out the excavation space, yet that effort can be chalked up to building soil fertility which has long-term benefits. On the other hand, soil cables and hot water piping systems might cost more up front, and require almost as much labor to install. But once purchased and installed, it offers superior flexibility with minimal effort. Depending on electrical costs and/or hot water heating methods, that heat might be affordable or costly to run per day. That cost should be understood in advance, and crops planted or raised in the hot bed should be worth the cost. The question of FSMA and GAP certification also needs to be considered. If a working farm wants to incorporate this practice into their early season plans, then issues of potential soilborne pathogen contamination must be considered and the heating system/designs chosen accordingly. On the other hand, a home gardener who only raises veggies for his/her own use, won't have those certification concerns.

Once the heat source is chosen and the frame constructed, the grower would still need to choose whether to direct-seed into the heated soil, or use transplants. Another consideration would be whether the plants will stay in that spot for the rest of the growing season, or be moved later in the season. If the former, make sure the heating source won’t interfere with the crop roots, and vice versa. For those frames using heating cables or radiators, consider whether you want to pull that system after growth has started. Pulling out the heat system after root growth has grown too far might actually set back the plants farther than they would have been had they not enjoyed the heat. One way to get around this is to actually seed into seedling trays, then set the seedling trays into the frame soil. After a suitable amount of growth has occurred and the season’s weather is more settled, those seedling trays can be transplanted elsewhere in the garden, thus allowing the grower to move or remove the heat source. However, many growers leave the heat source in place for the season, then pull it in fall after the crops have been harvested. With the traditional compost-as-heat-source, of course that manure is simply left in place as a soil amendment.

Our Experiences

We have not yet used hot frames, despite years of wanting to do so. Our experiences with cold frames inspired us to refine that frame design first before we moved forward with the heating addition. We have been reviewing our season extender options, and we definitely need to use every tool in that toolbox. Experimenting with the various systems, particularly those which we haven’t used yet, will give us greater flexibility as well as additional fodder for the website. So we will almost certainly use them at some point in the near future.

As I’ve been reviewing these variables, I find myself coming back over and over again to the benefits of the traditional composting system rather than the man-made system. That is almost purely because our farm is a mixed operation, with a healthy amount of animal manures available right here on-site. We have been working to streamline and refine our composting process to provide for more standard soil applications. But we certainly have plentiful access to fresh manures. And I like that we would bury the manures then be basically done with soil fertility for that bed for that year. The trick will be meshing that particular application of manure, and the use of the hot frames, with our existing crop rotation amongst the beds. We also fall under the new FSMA rules, and may someday seek GAP certification. So those two complications will need to be figured into the whole design. We might have to simply dive in and get started with a small number of beds, then redesign the rotation for those beds from that point forward, to ensure we gain the benefits from these frames while avoiding any regulatory headaches. Always more planning to be done. But whatever our experiences, we’ll share them here.

Additional Resources

Many of the additional PDF references we provided in the Cold Frames section provide information on building hot frames as well. Yet a few reports focus exclusively on frames which provide heat in some way:

This set of hot frame plans from the University of Missouri provide suggestions for using either fresh manure or heating cables. They are only plans, and provide very little additional text.

This very nice bulletin from Purdue University describes both cold frame and what they call "hotbed" construction. The bulletin features plans, as well as a fair amount of information about things like adequate ventilation, drainage, heat control, etc.

The University of Kentucky has published a very helpful bulletin called Hotbeds for Transplant Production, which has an extensive section on heating cable selection, installation and use. This bulletin also is the only publication I've ever seen which talks about heating a frame via the use of hot air, heated via wood stove and distributed throughout the frame via a flue network. Very interesting system for those who have access to lots of wood for such a heat source.

Ongoing Research

Some would predict that hot frames are on the way out, given all the alternatives now available. I don't think so - enough small scale gardeners and growers are happy to use low-tech and proven methods over new-fangled methods. Given that, I anticipate ongoing research and new findings released periodically. We'll publish them here if/when we become aware of them. If readers learn of additional resources, please Contact Us with the details and we'll be happy to add them here.

Where To Buy

As we saw with cold frames, hot frame kits and pre-assembled frames are easily available from a wide variety of sources, both local and online. Yet most growers choose to simply build their own, according to their own needs, plans and available materials. Animal manures are typically chosen only when those materials are free, so growers wanting to use this option would need to either already have livestock or ready access to a nearby source. Cow and horse manures are considered excellent manure types, so nearby riding stables, beef operations or dairies are potential suppliers. However, be sure to get fresh manure rather than pulling from some aged pile where all the nutrients have already leached out. Those piles are not nearly as potent for composting as fresh material. Also be sure to ask whether the animals had received worming treatments or other medications in the recent past; whatever drugs have been given to the livestock will end up in your soil. Some of those drugs are NOT destroyed in the composting process, so know what you’re getting.

Heating cables can be purchased from dedicated greenhouse suppliers, some home improvement stores, and online. They are not yet so common as to be available at smaller general retailers who only stock the most popular items. Shop carefully for the best prices because those prices can vary considerably. Hot water radiator systems, on the other hand, are not something generally sold as kits or completed products. The grower typically designs that system and builds it according to their own criteria. That system also generally needs some existing way to provide cost effective hot water, such as a boiler already in use for other on-farm tasks. In that instance, plumbing a system from that boiler would simply be an extension of the existing system. Those are almost always custom designed and built either by the grower or by a contractor.

Our Successful Farming and Ranching Books

We released our very first self-published book. The Chicken Coop Manual in 2014. It is a full color guide to conventional and alternative poultry housing options, including 8 conventional stud construction plans, 12 alternative housing methods, and almost 20 different design features. This book is available on Amazon.com and as a PDF download. Please visit The Chicken Coop Manual page for more information.

Rabbit Colonies: Lessons Learned

We started with rabbits in 2002, and we've been experimenting with colony management ever since. Fast forward to 2017, when I decided to write another book, this time about colony management. The book is chock-full of practical information, and is available from both Amazon and as a PDF download. Please visit the Rabbit Colonies page for more information.

The Pastured Pig Handbook

We are currently working on our next self-published book: The Pastured Pig Handbook. This particular book addresses a profitable, popular and successful hog management approach which sadly is not yet well documented. Our handbook, will cover all the various issues involved with pastured hog management, including case studies of numerous current pastured pig operations. If you have any questions about this book, please Contact Us.